Project Funding

We do funding for all types Road and Bridge Projects like NHAI,MORTH,NH,PWD and Water Projects In INDIA. We have experienced and well known finance experts to make processes in mint way.

Bridge Bearings

Elastomeric Bearing

| Business Type | Material | Color | Finishing | Bore Size | Specialities | Usage | Brand Name |

|---|---|---|---|---|---|---|---|

| Manufacturer, Trader | Rubber | Black | Coated | 0-8mm | Fine Finish | Bridge Use | Deevin |

Elastomeric Bearings support simultaneous load and deformation in any direction. Horizontal movements up to approximately one half of the rubber thickness and Rotations are allowed by the flexibility of rubber Depends upon the load capacity, Elastomeric bearing divides into two categories Plain Elastomeric and Laminated Elastomeric as shown for your reference. Steel plates are bonded to the rubber through a vulcanization process and have the main scope to increase the resistance of the bearings to vertical loads.

Metallic Guided Bearing

| Business Type | Thickness | Specialities | Material | Finishing | Brand Name | Country of Origin |

|---|---|---|---|---|---|---|

| Manufacturer, Trader | 3-80mm | Shear Strength, Precise Design | Metal | Coated | Deevin | India |

Fixed Pot Bearing

| Business Type | Type | Material | Thickness | Weight | Specialities | Finishing | Brand Name |

|---|---|---|---|---|---|---|---|

| Manufacturer, Trader | Pot PTFE Bearing | Metal | 8-30mm | 5kg, 10kg | Precise Design, Fine Finish | Coated | Deevin |

A Fixed Pot Bearing can bear the vertical loads and transfers the horizontal force in any direction. It also allows the rotation about any axis in the horizontal plane.

Fixed Spherical Bearing

| Business Type | Type | Material | Thickness | Weight | Specialities | Finishing | Brand Name |

|---|---|---|---|---|---|---|---|

| Manufacturer, Trader | Bearings | Metal | 3-80mm | 2kg, 5kg | Shear Strength, Precise Design | Coated | Deevin |

Finger Type Expansion Joint

| Business Type | Type | Material | Application | Color | Finishing | Feature | Brand Name |

|---|---|---|---|---|---|---|---|

| Manufacturer, Trader | Bearings | Metal | Bridge Use | Metalic, Silver | Polished | High Strength | Deevin |

Deevin's finger joint consists of multi-directional displacement hinge, sliding finger plate, fixed finger plate, support bracket, anchorage, and drainage system. The multi-directional displacement hinge is the key component of the finger joint, with capacity to accommodate the bridge three-dimensional deformation demands.

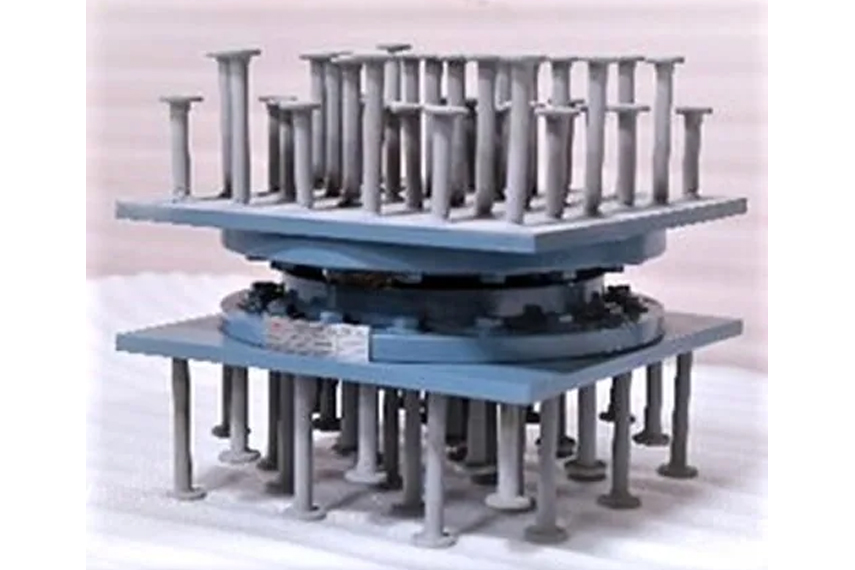

Modular Expansion Joint

| Business Type | Size | Type | Material | Application | Color | Finishing | Feature | Brand Name |

|---|---|---|---|---|---|---|---|---|

| Manufacturer, Trader | Available In Different Sizes | Expansion Joints | Metal | Industrial Use, Machine Use, Bridge Use | Metalic, Silver | Polished | Fine Finishing | Deevin |

Deevin's Modular joint systems represent the state-of-the-art approach to accommodating the large movements of long-span bridges. By incorporating the results of recent research activities, each joint system is designed to provide watertight, fatigue resistant, long-term, maintenance-free performance. Modular expansion joint assemblies are subjected to millions of high dynamic stress cycles due to passing vehicle loads. Recognizing the significance of these dynamic loads on the long-term performance of expansion joint systems. Each modular expansion joint system not only bridges the joint gap but also protects the structure from premature corrosion.

Strip Seal Expansion Joint

| Business Type | Material | Application | Color | Feature | Finishing | Thread Size | Brand Name |

|---|---|---|---|---|---|---|---|

| Manufacturer, Trader | Metal | Bridge Use, Construction | Metalic, Silver | Durable, Fine Finishing | Polished | 1/2inch, 1inch, 2inch, 3/4inch | Deevin |

Deevin's Strip Seal joint consists of an elastomeric sealing gland mechanically locked between two edge beams designed to provide the highest standard of performance. These Joints are designed for use on vehicular bridge structures, support heavy loads and efficiently accommodate multi directional movements including horizontal shear, vertical deflection and rotational movements.

Octagonal Electric Poles

Process Methods:

Thermal(Plasma) Cutting, Profile Bending, Submerged Arc Welding, Gas Metal Arc Welding, Grinding, Hot Dip Galvanizing & Straightening

Sizes/Ranges:

Up to 12 meters Length

Raw Materials Specifications:-

Pole Main Structure - HR Sheet T 3.0 mm as per IS:2062 E-350 C

Base Plate - MS Plate T 20 mm as per IS:2062 E-250 A

Surface Finishing:-

Hot Dip Galvanized (550 g/m²) - As per IS:2629

Foundation Bolts & Nuts:-

Process Methods:-

Length Cutting, Profile Bending, Threading & Electroplating

Sizes/Ranges:

J- Bolt - M 24 x 750mm to 1000mm Length

Hex Nut & Washer - M 24

Raw Materials Specifications:-

J- Bolt - ø 25mm bar as per EN8D Grades (BS 970)

Hex Nut & Washer - M 24 as per IS:1367/1364

Surface Finishing:- Electroplating

Sign Boards and Safety devices

The purpose of road traffic & safety signs is to promote road safety and efficiency by providing for the orderly movement of all road users on all roads in both urban and non-urban areas.

This Code contain the basic principle that govern design and use of road sign for all categories of road including expressways open to public travel irrespective of road agency having jurisdiction.

A road sign should meet the following basic requirements:

Fulfill a need.Command attention.

Convey a clear and simple meaning.

Command respected from road user.

Give adequate time for response.

Maintenance of road sign.

Placement and operation of road signs.

Uniformity of road signs.

Traffic engineering study.

The decision to use a particular sign at a particular location should be made on the basis of traffic engineering study and after a very careful planning so that correct and uniform signs are placed at required locations.

W-Beam Structural Elements:

Process Methods:

Length Cutting, Thermal(Plasma) Cutting, Drilling, Gas Metal Arc Welding, Powder Coating, Pasting & Riveting Sizes/Ranges:

Single PostDouble Post

Place Identification Boards

Advance Direction Boards

Overhead Cantilevers Boards

Overhead Gantry Boards

Toll Boards

Variable Message Sign (VMS)

Smart City Overhead Gantries, Cantilevers, RLVD Poles & Other Sign Boards

And other customized unique products for client's needs.

Raw Materials Specifications:

Retro Reflective Sheeting - DG, ASTM D 4956 Type-XI Make 3M

Aluminium Composite Panels - HR Sheet T 4.50 to 5.0 mm as per IS:2062 E-250 A

Post & Structural Assembly - MS Pipe ø 88.9 x T 2.5 mm, ø 219 x T 4.0 mm, ø 324 x T 5.0 mm as per IS: 1161/1239/3601 YST-210

Frame Assembly - MS L-Angle W 25 x W 25 x T 3.0 mm as per IS:808 & MS Tube W 20 x H 40 x T 2mm as per IS:4923 YST-210

Surface Finishing:

Black Powder Coating on full parts & White Strips on Post & Structural Assembly

Note:

Specification of raw materials and surface finishing can be customized to client's needs.

Metal Beam Crash Barrier

Crash Barriers are provided to ensure high resistance in crash impact because of its flexible beam action. In this way it minimizes the speed of vehicle and also increases the driver confidence while riding through any critical area. It also increases visibility at night or in foggy conditions.

Our range of metal beam crash barriers consists of two variants W-Beam &Thrie Beam as per MORTH Clause 811.3 & IRC: SP: 84, IRC: SP:87, IRC: SP: 99 & IRC: 119 & IRC:5

It is qualified to crash testing ‘Road Restraint System’ as per European EN 1317-2 Standard & results are satisfactory as per the requirements of MORT&H Guideline: RW/NH-29023/02/2019-S&R (P&B), Dated :01st January,2020

Crash Barriers are provided to ensure high resistance in crash impact because of its flexible beam action. In this way it minimizes the speed of vehicle and also increases the driver confidence while riding through any critical area. It also increases visibility at night or in foggy conditions.

Our range of metal beam crash barriers consists of two variants W-Beam &Thrie Beam as per MORTH Clause 811.3 & IRC: SP: 84, IRC: SP:87, IRC: SP: 99 & IRC: 119 & IRC:5

It is qualified to crash testing ‘Road Restraint System’ as per European EN 1317-2 Standard & results are satisfactory as per the requirements of MORT&H Guideline: RW/NH-29023/02/2019-S&R (P&B), Dated :01st January,2020

Metal Beam Crash Barriers are manufactured by using the Cold Roll Forming Technology with multiple roll forming stations. This enables us to achieve our productivity and targets on regular basis along with greater quality and accuracy.

W-Beam Structural Elements:

Process Methods:

Cold Roll Forming, Piericing, Shearing, Profile Bending, Hot Dip Galvanizing

Sizes/Ranges:

W-Beam - L 4318 x W 312 x H 81 x T 2.50 to 3.0 mm

End Section - L 736 x W 312 x H 81 x T 2.50 to 3.0 mm

Post - L 1100 to 1800 x W 150 x H 75 x T 4.50 to 5.0 mm

Spacer - L 330 to 360 x W 150 x H 75 x T 4.50 to 5.0 mm

Bolts & Nuts (Hex/Button head) - M16 x P 2.5 x L 40m

Raw Materials Specifications:

W-Beam/End Section - HR Sheet T 2.50 to 3.0 mm as per IS:1079 HR3 / IS:2062 E-250 A

Post & Spacer - HR Sheet T 4.50 to 5.0 mm as per IS:2062 E-250 A

Bolts & Nuts (Hex/Button head) - M16 as per IS:1367 / 136

Surface Finishing:

Hot Dip Galvanized (550 g/m²) - As per IS:2629

Note:

Specification of raw materials and surface finishing can be customized to client's needs.

Thrie-Beam Structural Elements:

Process Methods:

Cold Roll Forming, Piericing, Shearing, Profile Bending, Hot Dip Galvanizing

Sizes/Ranges:

Thrie-Beam - L 4318 x W 502 x H 81 x T 2.50 to 3.0 mm

End Section - L 760 x W 502 x H 81 x T 2.50 to 3.0 mm

Post - L 2000 to 2100 x W 150 x H 75 x T 4.50 to 5.0 mm

Spacer - L 550 x W 150 x H 75 x T 4.50 to 5.0 mm

Bolts & Nuts (Hex/Button head) - M16 x P 2.5 x L 40mm

Raw Materials Specifications:

Thrie Beam/End Section - HR Sheet T 2.50 to 3.0 mm as per IS:1079 HR3 / IS:2062 E-250 A

Post & Spacer - HR Sheet T 4.50 to 5.0 mm as per IS:2062 E-250 A

Bolts & Nuts (Hex/Button head) - M16 as per IS:1367 / 1364

Surface Finishing:

Hot Dip Galvanized (550 g/m²) - As per IS:2629

Geo-Composite and Geo Strap

| Business Type | Material | Packaging Type | Color | Break Strength | Pattern | Place of Origin | Brand Name |

|---|---|---|---|---|---|---|---|

| Manufacturer, Trader | Polyester | Roll | Black | 30-100 kn | Plain | India | Deevin |

The strips consist of distinct channels of tightly packed high tenacity polyester (PET) yarn encased in polyethylene sheath. The strips are suitable for reinforcement applications in combination with concrete wall facing panels.

Bus Shelters

Process Methods:

Thermal Cutting, Length Cutting, Profile Bending, Croping, Gas Metal Arc Welding, Painting

Sizes/Ranges:

As per customer designs

Raw Materials Specifications:

As per customer needs

Surface Finishing:

As per customer needs

Process Method: Thermal Cutting,pipe Cutting, Profile bending,Cropping,GMAW & Painting

Size/Range: As per Drawing or Customer Requirement

Raw Material Specifications:

MS Pipe of OD 127xT 2.5mm as per IS:1161/IS:3601/IS:1239

MS Pipe of OD 88xT 2.5mm as per IS:1161/IS:3601/IS:1239

MS Pipe of OD 48xT 2.3mm as per IS:1161/IS:3601/IS:1239

MS Pipe of OD 26xT 2.3mm as per IS:1161/IS:3601/IS:1239

MS Tube of 20x40x2mm as per IS:4923

MS Plate of Thick 12mm as per IS:2062

S Sheet of Thick 3mm as per IS:2062

CR Sheet of Thick 1mm as per IS:513

Surface Finishing: Powder Coating or as per customer Requirements

GFRP Rods Details

Light Weight .

◆ High Tensile Strength.

◆ Corrosion Resistance.

◆ Anti-static Conditioning.

◆ Excellent cuttability.

◆ No-conductive(electric, thermal).

◆ Flame Resistance.

◆ Continuous threaded profile.

◆ Flexibility.

◆ No electrical conductivity.

◆ Wide range of various dimensions.